RXR-MC200BD Explosion-proof Fire Fighting Reconnaissance Robot

Product description

RXR-MC200BD explosion-proof fire extinguishing reconnaissance robot is a kind of special robot. It uses lithium battery power as the power source and uses wireless remote control to remotely control the fire extinguishing robot. The robot is mainly composed of a robot body, a large-flow water cannon, an explosion-proof infrared dual-vision pan/tilt, audio and video reconnaissance, toxic and harmful gas reconnaissance, and a handheld remote control terminal. It is applicable to fires in highway (railway) tunnels; fires in subway stations and tunnels; fires in underground facilities and freight yards; fires in large-span and large-space places. It is especially suitable for fires in petrochemical oil depots and refineries; attack and cover of dangerous fire targets; fire fighting and rescue of inaccessible fires. This product has the functions of fire fighting, audio and video reconnaissance, toxic and hazardous gas reconnaissance, and environmental reconnaissance in disaster areas;

Scope of application

● Large-scale petrochemical enterprises, tunnel and subway fire rescue

● On-site rescue of hazardous chemical fires or dense smoke fires

● On-site rescue of oil, gas, poisonous gas leakage and explosion, tunnel, subway collapse, etc.

Features

1. ★Strong fire extinguishing ability

The design of large-flow duckbill water cannon can change a variety of water spray forms, the spray flow can be adjusted, and the range is high, which can meet the fire fighting work in large spaces.

2.★High protection level

The overall protection level is IP67

Chassis protection grade is IP68

3.★Various types of toxic and harmful gas detection

Up to 8 kinds of gases, 2 kinds of environmental parameters

4. ★Strong power

Strong ability to tow hoses, can drag 6 80 hoses at the same time

5. ★Multifunctional use

It has the functions of fire extinguishing, reconnaissance, transportation, especially the transportation of rescue equipment and materials such as hose equipment (such as: hose, gas mask, positive pressure air breathing apparatus, fire protection clothing, rescue tools and other equipment)

6. ★Access to the robot networked cloud platform

Real-time status information of the robot’s location, power, audio, video, gas environment detection information, etc., can be transmitted to the cloud through the 4G/5G network, and can be viewed on the back-end PC and mobile terminals

Main Specifications

4.1 The whole robot:

1. Name: Explosion-proof fire-fighting reconnaissance robot

2. Model: RXR-MC200BD

3. Basic functions: fire fighting, audio and video reconnaissance, toxic and hazardous gas reconnaissance, environmental reconnaissance in disaster areas;

4. Implementation of fire protection industry standards: “GA 892.1-2010 Fire Robots Part 1 General Technical Requirements”

5. Implementation of explosion-proof standards: GB3836.1 2010 “Explosive Environment Part 1: General Requirements for Equipment”, in line with GB3836. 1-2010 “Explosive Environment Part 2: Equipment Protected by Flameproof Enclosures”, CB3836. 4 2010 ” Explosive environment Part 4: Intrinsically safe protection equipment National Standard

6.★Explosion-proof type: Exd [ib] Ⅱ B T4 Gb of the whole robot (this parameter is consistent with the inspection report of the National Coal Mine Explosion-proof Safety Product Quality Supervision and Inspection Center)

7. ★Protection level: the protection level of the robot body is IP68, and the protection level of the upper part of the robot is IP67 (this parameter is consistent with the test report of the Testing Center of the China Coal Research Institute)

8. Power: electric, lithium battery

9.★Size: length 2800mm×width 1730mm×height 1470mm

10. ★Steering diameter: turning in place

11.★Weight: 2800kg

12. ★Traction force: 20000N

13. Dragging distance: ≥100m (towing two DN80 enriched hoses)

14.★Maximum flow: 200L/s (150L/s~200L/s flow adjustment)

15. ★Maximum linear speed: ≥1.6m/s, remote control stepless speed

16. ★ Straight deviation amount: ≤ 2%

17.★Climbing ability: 84% (or 40°)

18. Obstacle crossing height: 400mm,

19. Roll stability angle: ≥40 degrees

20. ★Wade depth: 600mm (atmospheric immersion in water for 1 hour without water)

21. Continuous walking time: 3h

22. Reliability working time: through 16 hours of continuous stability and reliability test

23. Remote control distance: 1110m

24. Video transmission distance: 1110m

25. ★Load capacity: self-carrying frame, which can transport rescue materials to the disaster site (such as: hose, gas mask, positive pressure air respirator, fire protection clothing, rescue tools and other equipment); can be towed Carrying a rescue vehicle into the rescue scene; it can pull obstacles through the towing ring

26. ★Panoramic monitoring function: can remotely display the 360-degree image of the robot body (this parameter is consistent with the test report of the National Fire Equipment Quality Supervision and Inspection Center)

27. ★ Attitude display function: real-time detection of the robot’s pitch angle, roll angle, and azimuth angle, so that the operator can try to grasp the robot state, and return the value to the remote control terminal for the next correct command operation (this parameter is related to the quality of the national fire protection equipment The inspection report of the supervision and inspection center is consistent)

28. Autonomous obstacle avoidance function: When encountering obstacles within 2 meters ahead, the speed is halved, and when encountering obstacles within 1 meter, it will automatically stop moving forward.

29.★Automatic spray cooling function: It has a three-layer water curtain self-spray cooling design, which sprays and cools the robot body to form a water curtain covering the whole robot, ensuring that the battery, motor, control system and key components of the robot are in Normal operation in high temperature environment; users can customize the alarm temperature (this parameter is consistent with the test report of the National Fire Equipment Quality Supervision and Inspection Center)

30. Automatic power generation and recoil suppression function: The main motor of the robot adopts power generation braking, which converts recoil force into electric energy in sprinkler fire extinguishing;

31.★Robot crawler: Fire-fighting robot crawler should be made of flame-retardant, anti-static and high-temperature resistant rubber (this parameter is consistent with the inspection report of the National Coal Mine Explosion-proof Safety Product Quality Supervision and Inspection Center); the interior of the crawler is a metal skeleton; it has a crawler anti-derailment protection design;

32. Waterproof belt knotting function (optional): through the double universal structure, it can be rotated 360 degrees to prevent the water belt from knotting

33. Automatic hose off function (optional): remote control operation realizes automatic hose off, ensuring that the robot can return lightly after completing the task

34. Control terminal: handheld remote control terminal with integrated picture and data

4.2 Robot fire extinguishing system:

1. Fire monitor: imported fire monitor

2. Type of fire extinguishing agent: water or foam

3. Material: gun body-stainless steel, gun head-aluminum alloy hard oxidation

4. Working pressure (Mpa): 1.0~1.4 (Mpa)

5. Spray method: flat duckbill water spray, direct current, low expansion foam

6.★Water/foam flow rate: 200L/s (150L/s~200L/s flow adjustment)

7. Range (m): ≥105m (water); ≥100m (foam)

8.★Rotation angle: horizontal -45°~45°, vertical 0°~90°

9. Maximum spray angle: flat spray, covering a 45-meter wide area

10. Foam tube: The foam tube can be replaced. The replacement method is threaded quick connection. The fire water monitor can spray water, foam and mixed liquid, so it can be used for multiple purposes, and there is no need to switch between DC and duckbill flattening Remove the foam cylinder

4.3 Robot Reconnaissance System:

By configuring gas instruments, environmental monitoring modules, infrared cameras, 360° visible light patrol and infrared thermal imaging systems, pickups and other vehicle-mounted equipment, it can remotely detect toxic and harmful gases at the accident site, environmental conditions in the disaster area, video, and audio; configure explosion-proof The lifting platform is equipped with environment detection sensors and cameras to realize the measurement and analysis of the toxic combustible gas, audio and video, and the environment at different heights on site;

1. ★Reconnaissance system configuration: 5 vehicle-mounted explosion-proof infrared cameras, explosion-proof 360° visible light patrol and infrared thermal imaging system, 1 multi-parameter tester, 1 temperature and humidity detector

2. ★The lifting height of explosion-proof lifting platform: initial height: 1370mm, height after lifting: 2170mm

3. ★Gas and environment sensing detection module: equipped with wireless emergency rescue rapid deployment detection system and temperature and humidity detector, which can detect: CO2: 0-5%VOL

CH4: 0-100%VOL

CO: 0-1000ppm

H2S: 0-100ppm

CL2: 0-1000ppm

NH3: 0-100ppm

O2: 0-30% O2

H2: 0-1000ppm

Temperature range: -25°C to 60°C

Humidity range: 0% RH to 90% RH

4.Infrared temperature measurement function: Infrared temperature measurement sensors are equipped inside and outside the car to monitor the internal temperature of the car body and the field temperature (-50-350°C)

4.4 Robot video and audio perception:

1.★ Number and configuration of cameras: The video system is composed of 5 fixed high-definition infrared cameras on the body, which realizes the viewing distance in the front direction and 360 panoramic images of the robot body; it is also equipped with a 360° visible light patrol and infrared thermal imaging system to detect the heat source And tracking

2. Camera illumination: The camera on the body can provide clear images under 0.001LUX low illumination, with dynamic anti-shake; the camera should be able to effectively and clearly capture the scene situation at zero illumination, and display it on the LCD screen of the operating terminal

3. ★Panorama monitoring function: can remotely display 360-degree images of the robot body

4. Camera pixels: million high-definition images, resolution 1080P, wide-angle angle 60°

5. ★ Camera protection level: IP68

6. Technical requirements for sound collection: remote collection of on-site sound, easy to understand the situation of trapped persons, pickup distance 5 meters, frequency range 20Hz~20kHz, sensitivity ≥40dB

7. Explosion-proof thermal imaging pan/tilt: thermal imaging resolution: 384*288;

Temperature measurement range: -20-550℃, observation radius of 100 meters;

Visible light multiple: 33 times;

Horizontal: 0-360°, vertical: -90~90°;

Detect and track heat sources; infrared thermal imager has image anti-shake function; has image acquisition and real-time transmission function; has visual fire source search function

4.5 Remote control terminal configuration parameters

1. Dimensions: 410*310*70mm (excluding rocker height)

2. Whole machine weight: 6.5kg

3. Display: no less than 10 inches high-brightness LCD screen, 4-channel video signal switching

4. Control system platform: window7 operating system

5. Working time: 8h

6. Basic functions: The remote control and the monitor are integrated and portable, with an ergonomic strap; they can be watched and controlled at the same time, and the environment around the scene can be stably presented to the remote controller, and the battery and robot can be displayed in real time Slope angle, azimuth angle status, toxic and harmful gas concentration alarm information, etc., control the robot’s forward, backward, and turn movements; control the water cannon to do up, down, left, right, direct current, atomization, self-swing and other actions. It has the function of image anti-shake; it has the function of collecting and real-time transmission of 360-degree panoramic images of the front, rear, and around the robot. The data transmission method is wireless transmission using encrypted signals.

7. ★Panorama monitoring function: can display 360-degree images of the robot body in real time

8.★Video recording and playback function: video can be recorded at any time, the recorded video content is automatically saved, the video can be played directly on the remote control terminal, or the video can be copied to other devices

9. ★With projection screen function: can be connected to projection equipment such as projectors through HDMI interface, which is convenient for operation commanders to discuss and make decisions together

10. Walking control function: Yes, one three-axis industrial joystick, one joystick realizes the flexible operation of robot forward, backward, left turn and right turn

11. Fire monitor control function: Yes, 1 three-axis industrial joystick, one joystick can control the water monitor to do up, down, left, right, DC, and atomization actions

12. Control and reconnaissance system lift switch: Yes, self-reset jog switch

13. Video switch: Yes, self-reset jog switch

14. Control the automatic tow belt function: Yes, self-reset jog switch

15. Lighting control function: Yes, self-reset jog switch, the host computer does self-locking response

16. Auxiliary tools: handheld remote control terminal shoulder strap, movable tripod

4.6 Internet function:

1. GPS function: GPS positioning, track can be queried

2. ★ It can be connected to the robot cloud management platform (optional): the robot name, model, manufacturer, GPS location, battery power, video, temperature, humidity, CO2, CO, H2S, CH4, CL2, NH3, O2 can be connected , H2 data is transmitted to the cloud management platform through the 4G/5G network, and the robot status can be checked in real time through the PC/mobile terminal. It is convenient for commanders to make decisions and equipment managers to manage the whole life cycle of robots

4.7 Other:

★Emergency transportation plan (optional): robot dedicated transport trailer or robot dedicated transport vehicle

Packing list

1.1. Explosion-proof fire-fighting reconnaissance robot×1

2.2. Handheld remote control terminal × 1

3.3. Car body charger (336V) × 1 set

4.4. Remote control charger (19.6V) × 1 set

5.5. Antenna (digital transmission) × 2

6.6. Antenna (picture transmission) × 3

7.7. Robot cloud management platform × 1 set (optional)

8.Robot emergency transport vehicle × 1 (optional)

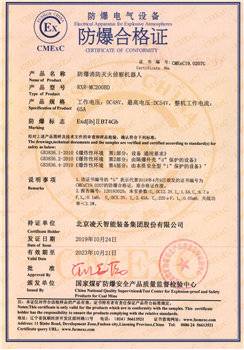

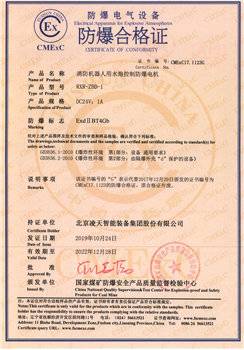

Certificate

1.1. Explosion-proof certification of the whole machine: Exd[ib]IIBT4Gb, provide original explosion-proof certificate for reference

2.2. Fire-fighting robot water cannon to control explosion-proof motor: ExdIIBT4GB, original explosion-proof certificate is provided for reference

3.3. ★Explosion-proof certification of gas and environment sensing detection module: ExdibIICT5GB, provide original explosion-proof certificate for reference

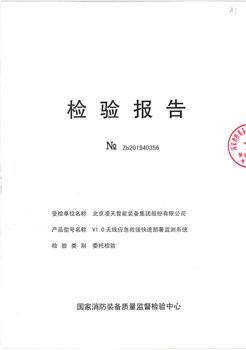

4.4. ★Fire certification for gas and environmental sensing detection module: passed the inspection of the National Fire Equipment Quality Supervision and Inspection Center, and provide the original for reference

5.5. ★Explosion-proof certification of explosion-proof lifting platform: ExdIIBT5GB, provide original explosion-proof certificate for reference

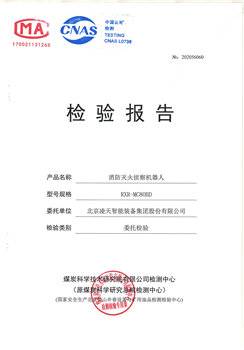

6.6. ★ Inspection report of crawler material for fire-fighting robots: inspection report of National Coal Mine Explosion-proof Safety Product Quality Supervision and Inspection Center

7.7.★Passed the inspection by the Testing Center of Coal Science and Technology Research Institute Co., Ltd., the protection level of the robot body is IP68, and the protection level of the upper part of the robot is IP67. The original parts are provided for reference

8.★The automatic water cut-off protection device obtained the invention patent through the State Intellectual Property Office, and the original is provided for reference